In the realm of culinary arts, innovative technologies have revolutionized the way we prepare and present food. Among these breakthroughs is the food extruder, a versatile machine that has gained immense popularity in professional kitchens and food production facilities. In this comprehensive guide, we will explore the wonders of a food extruder, its functionality, and the countless benefits it offers. Whether you're a chef, food manufacturer, or simply an avid food enthusiast, this article will provide you with valuable insights into the world of food extrusion.

1.1 What is a Food Extruder?

A food extruder is a state-of-the-art machine designed to transform various food ingredients into specific shapes and textures. It utilizes a combination of heat, pressure, and mechanical force to process raw ingredients, creating an array of culinary delights. From pasta and snacks to breakfast cereals and pet food, the food extruder offers endless possibilities in the world of gastronomy.

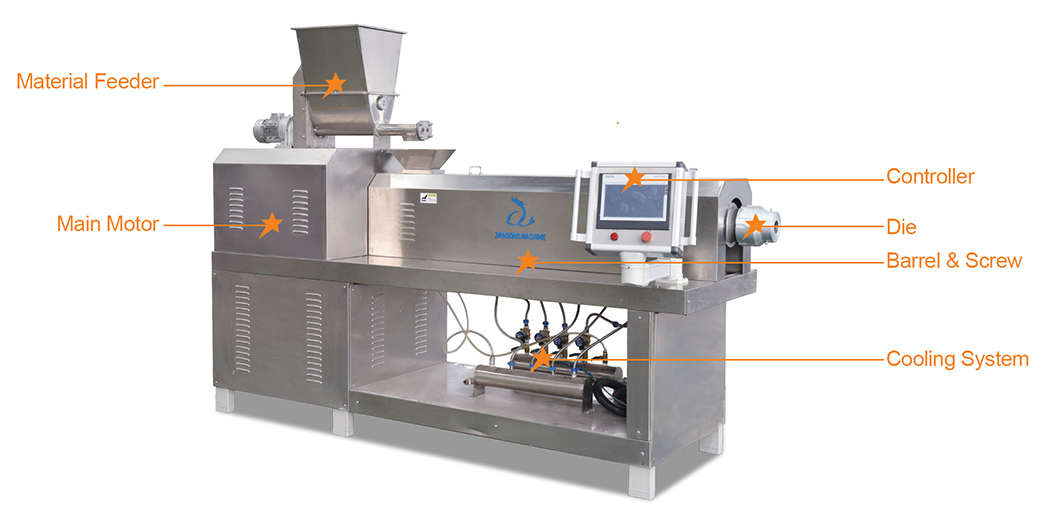

1.2 How Does a Food Extruder Work?

The working principle of a food extruder involves a precise balance of heat, pressure, and shear forces. The raw ingredients, mixed with water or other liquid components, are fed into the extruder's chamber. Inside the chamber, a rotating screw applies pressure and friction, causing the ingredients to heat up and undergo physical and chemical transformations. The resulting mixture is then extruded through a die, which shapes the food into desired forms such as noodles, pellets, or flakes.

2.1 Enhanced Nutritional Value

Food extrusion helps retain the natural nutritional value of ingredients by minimizing the loss of essential vitamins, minerals, and proteins during processing. The short processing time and controlled heat exposure ensure that the final product maintains its nutritional integrity.

2.2 Versatility in Product Development

The food extruder offers remarkable flexibility in product development, allowing chefs and manufacturers to experiment with various ingredients and create unique textures, shapes, and flavors. This versatility opens up a world of opportunities for culinary innovation.

2.3 Improved Production Efficiency

Food extruders streamline the production process by automating several stages, reducing manual labor and saving time. With higher production capacities, businesses can meet growing demand and maintain consistent quality without compromising efficiency.

2.4 Consistent Product Quality

The precise control over extrusion parameters enables the production of consistent product quality, ensuring that every batch meets the desired specifications. This reliability is crucial for food manufacturers aiming to establish a loyal customer base.

3.1 Snack Food Industry

The snack food industry has greatly benefited from the food extrusion technology. Extruders are used to create a wide range of snacks, including potato chips, puffed rice cakes, and extruded corn snacks. The ability to control texture, flavor, and appearance has made food extrusion an indispensable tool in snack production.

3.2 Pasta and Noodle Production

Traditional pasta and noodle making processes often require extensive manual labor and time. Food extruders have revolutionized this industry by automating the process, allowing for consistent and efficient production of various pasta shapes and noodle varieties.

3.3 Pet Food Manufacturing

Food extrusion plays a vital role in the production of pet food. It enables the creation of nutritionally balanced and easily digestible pet food products. Extruders can process a wide range of ingredients, including meat, grains, and vegetables, resultingin high-quality pet food with optimal nutrient content.

4.1 Considerations for Selection

When choosing a food extruder machine, several factors should be taken into account. These include production capacity, versatility, ease of maintenance, and the availability of spare parts. It is important to assess the specific needs and requirements of your culinary operation to make an informed decision.

4.2 Working with Experts

Consulting with food extrusion experts or suppliers can provide valuable guidance in selecting the right machine for your business. They can offer insights into the latest technological advancements, provide demonstrations, and help you understand the various features and specifications of different models.

The food extruder is a game-changer in the culinary world, offering unmatched efficiency, versatility, and product quality. From enhancing nutritional value to streamlining production processes, this innovative technology has paved the way for culinary innovation across various industries. Embracing the possibilities of food extrusion can unleash a world of gastronomic creativity and efficiency.

Previous: How Does an Automatic Bottle Palletizer Work?

Next: Benefits and Advantages of Bottle Bagging Machine in Packaging Industry

Comments

Please Join Us to post.

0